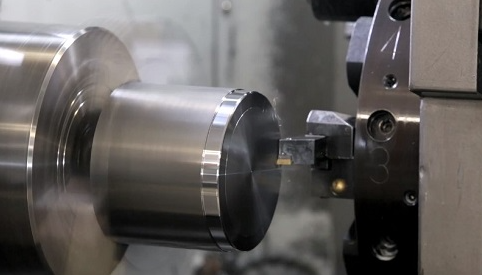

Dukanmu mun ci karo da matsalar workpiece surface chatter a lokacin CNC juya.Maganar haske yana buƙatar sake yin aiki, kuma mai nauyi mai nauyi yana nufin tarwatsewa.Ko ta yaya aka sarrafa shi asara ce.Yadda za a kawar da chatting a kan aiki surface naFarashin CNC?

Yadda Ake Cire Chatter & Vibration Of Operating Surface A cikin Juyawar CNC

Domin kawar da chatter na aiki surface a CNC juya, muna bukatar mu san dalilin chatter.

1. Matsalolin inji

Akwai dalilai guda biyu masu yiwuwa na kayan aikin injin.

(1) Lokacin da workpiece aka jacked tare da saman murfin, da jacking tsawo ne da yawa, sakamakon rashin isa ga rigidity.

(2) An yi amfani da injin kanta na dogon lokaci, kulawar ba ta dace ba, kuma abubuwan ciki da sauran sassa suna sawa sosai.

2. Kayan aiki

Akwai dalilai hudu masu yiwuwa na kayan aikin injin.

(1) Sauran kayan aikin yana kara tsayi da yawa yayin juyawa, yana haifar da rashin isasshen ƙarfi.

(2) Ana sawa ruwa ba kaifi ba.

(3) Zaɓin ma'auni na kayan aikin injin yayin juyawa ba shi da ma'ana.

(4) Tushen baka na ruwa ya yi girma da yawa.

3. Matsalolin Aiki

Akwai dalilai guda uku masu yiwuwa ga kayan tarihi.

(1) Kayan aikin juyawa yana da wuyar gaske, wanda ke shafar juyawa.

(2) Juyawa workpiece yayi tsayi da yawa, kuma kayan aikin ba su da ƙarfi sosai yayin jujjuyawar.

(3) Na bakin ciki bango workpieces ba m isa lokacin juya excircles.

Idan girgiza ya faru a lokacin juyawa, ta yaya za a kawar da matsalar?

1. Kayan aiki

Da farko, bincika ko akwai matsala tare da kayan aikin.

(1) Idan kayan aikin da za a juya yana da wuyar gaske, za ku iya canza tsarin don rage taurin aikin, sannan ku inganta shi ta wasu hanyoyi daga baya.

(2) Idan kayan aikin da za a juya ya yi tsayi da yawa, bi mariƙin kayan aiki don inganta kwanciyar hankali na aikin.

(3) Idan workpiece ne bakin ciki-bangon, kayan aiki za a iya tsara don inganta rigidity lokacin da juya excircle.

2. Kayan aiki

Na gaba, bari mu ga ko matsalar kayan aiki ce.

(1) Idan kayan aikin ya ƙare na dogon lokaci, duba ko za a iya daidaita matsayi na ƙananan kayan aiki.Idan ba haka ba, maye gurbin kayan aiki tare da karfe mafi girma.Idan ya cancanta, yi amfani da hutun kayan aikin anti vibration.

(2) Idan an sa ruwa, maye gurbin ruwa.

(3) Idan dalilin shine cewa sigogin injin da aka zaɓa ba su da ma'ana, canza shirin kuma zaɓi sigogi masu dacewa.

(4) Tushen baka na kayan aiki ya yi girma sosai, kuma ana buƙatar maye gurbin ruwa.

3. Kayan aikin injin

A ƙarshe, yanke hukunci ko akwai matsala tare da kayan aikin injin kuma ko an yi amfani da titin kayan aikin da bai dace ba

(1) Idan an yi amfani da saman da bai dace ba, saman tare da kyakkyawan aiki yana buƙatar maye gurbinsa.

(2) Idan an yi amfani da kayan aikin na'urar kanta na dogon lokaci kuma kulawa ba ta dace ba, wajibi ne a tuntuɓi ma'aikatan kula da kayan aikin na'ura don gyara kayan aikin na'ura.

Idan Ba a sami matsala fa?

Idan ba mu sami wata matsala ba bisa abubuwan da ke sama, me kuma za mu iya yi?Yana iya dogara ne akan bincike akan ka'idar girgizar saitin kayan aiki.A halin yanzu, akwai wasu takamaiman hanyoyi masu amfani da ake amfani da su zuwa wurin sarrafawa:

(1) Rage nauyin aiki na sassan da ke haifar da rawar jiki, kuma ƙarami da rashin aiki, mafi kyau.

(2) Don kayan aikin eccentric, yi kayan aiki masu dacewa.

(3) Gyara ko matsa sassan tare da mafi girman girgiza, kamar firam ɗin tsakiya, kejin aiki, da sauransu.

(4) Ƙara ƙarfin tsarin sarrafawa, alal misali, yi amfani da mariƙin kayan aiki tare da babban ma'auni na roba ko amfani da karfi na anti vibration na musamman wanda aka haɗe tare da damper mai ƙarfi don ɗaukar makamashi mai tasiri.

(5) Daga ra'ayi na ruwa da workpiece juyawa shugabanci.

(6) Canja siffar kayan aiki da kusurwar ciyarwa, ƙananan radius tip na kayan aiki shine, mafi kyau, kuma rage juriya na yanke.Dole ne kusurwar karkata ta kasance mai inganci don sanya jagorar yankan kusa da tsaye.Kwancen simintin ya fi kyau ya zama tabbatacce, amma ko da ikon cire guntu ba shi da kyau, ana iya amfani da shi gabaɗaya don sanya kusurwar simintin mara kyau, amma har yanzu yana riƙe ingantaccen ƙimar sakamakon yanke.

Lokacin aikawa: Oktoba-22-2022